ADVANTAGES OF LED

ILLUMUS offers a complete lineup of LED products that adhere to current national quality compliance standards including Energy Star, Design Lights Consortium (DLC), and various California specific specifications (Title 24, JA8, etc).

LONG LIFE TIME

LEDs have a longer rated life than traditional light sources. Depending on the application, the rated lifetimes of LED lamps and luminaires can be 10 – 50 times that of traditional light sources. This extended lifetime brings the benefits of reduced maintenance costs as well. ILLUMUS’s SpecFit family is rated at 100,000 hours, twice the industry norm.

HEAT GENERATION

In contrast to metal halide, incandescent and fluorescent sources, LEDs radiate very little heat that can cause damage to sensitive objects or discoloration of fabrics and finishes. Reduced heat generation also brings potential savings on air-conditioning costs. HID retrofit lamps from ILLUMUS provide the right amount of light without all the heat from traditional metal halide lamps.

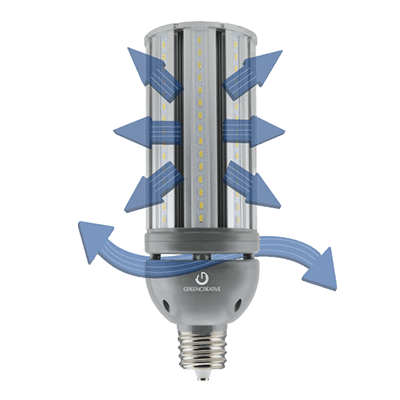

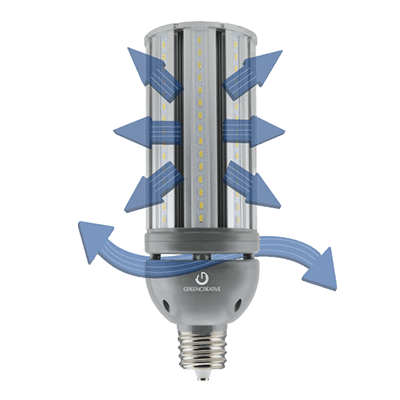

DIRECTIONALITY

Due to their small form factor, LEDs present the best of both worlds for lighting design. They can be used to mimic the directionality of PAR, BR and MR lamps or be combined to duplicate the omnidirectional nature of fluorescent and incandescent sources.

ENVIRONMENT FRIENDLY

Unlike Fluorescent lamps that may have up to xx% of mercury, LED lamps are completely mercury free and dramatically reduce their environmental impact upon disposal.

INSTANT-ON

Unlike fluorescent lamps that take time to warm up and come to full brightness or metal halide lamps that need time to cool down before they can be restarted, LEDs are near full brightness almost instantly and can be rapidly cycled without any harmful effects the rated lifetime or light output.

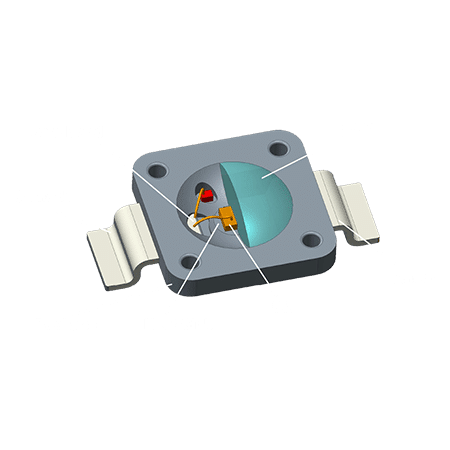

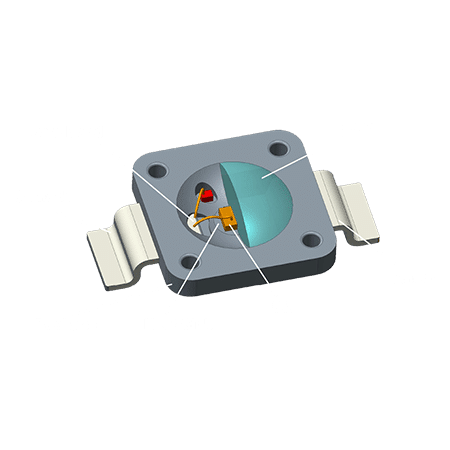

LED PACKAGE COMPOSITION

The LED chip or die cannot be used independently but must be packaged into a lighting system before it can be used in an application. When referring to LED lighting, we usually refer to the LED package.

The main package components are:

Semiconductor die or chip: This is the central component of the package that creates light. LED chips are only produced by a handful of integrated companies such as CREE, Bridgelux, Lumiled in the US, Osram in Germany, Nichia or Citizen in Japan or Seoul in Korea…

Phosphor layer placed on top of the blue LED chip to achieve white light

Heat sink which transfers the heat away from the chip

Electrodes (anode and cathode) that transfer the current from the device to the package

Bond wire which will link the electrodes to the die or chip

Primary lens which will control the beam

THIRD PARTY MANUFACTURER

The LED package can be manufactured by the chip manufacturer or by a third party packaging company such as Dominant in Malaysia, Edison in Taiwan or hundreds of smaller ones mainly located in China.

The advantages of a full package by a chip manufacturer over a third party package:

Higher efficiency, Slower lumen depreciation, Lower thermal resistance, Higher CRI, Better color consistency and maintenance, Better overall performance and quality consistency

Thus, for very demanding commercial applications where high performance and longer lifetime is required, a full package from a chip manufacturer will be used. All GREEN CREATIVE products use full package from chip manufacturer.

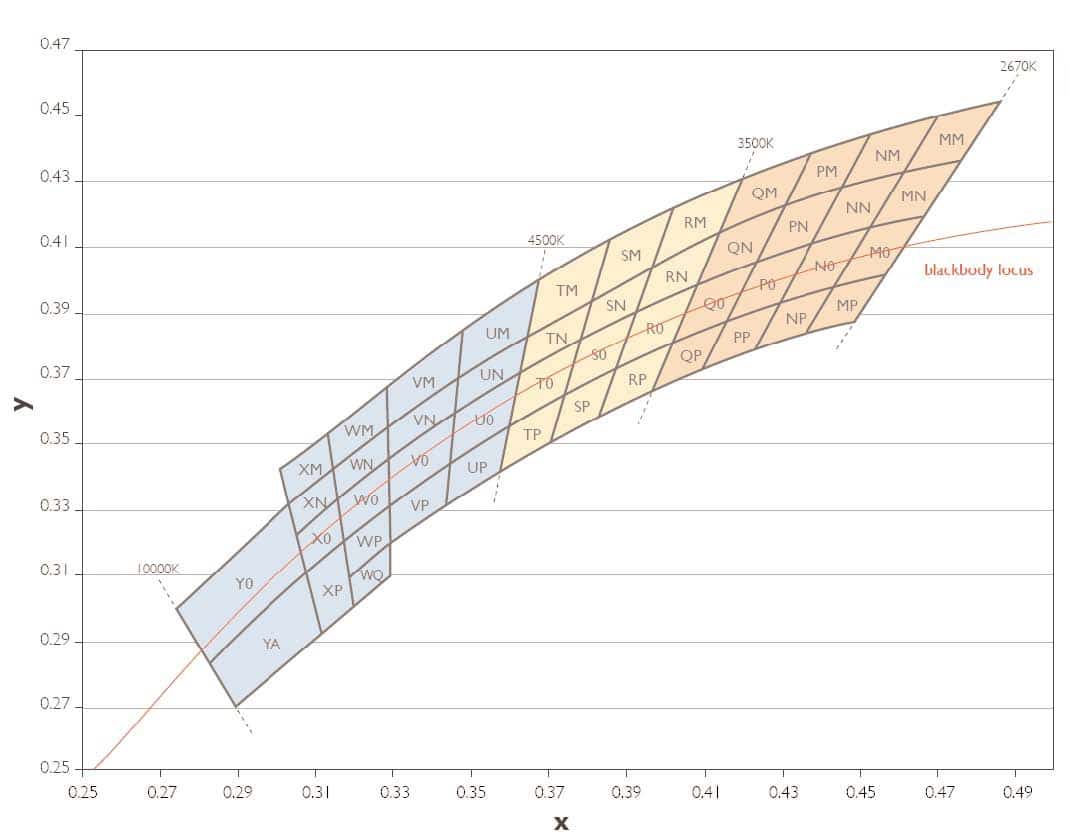

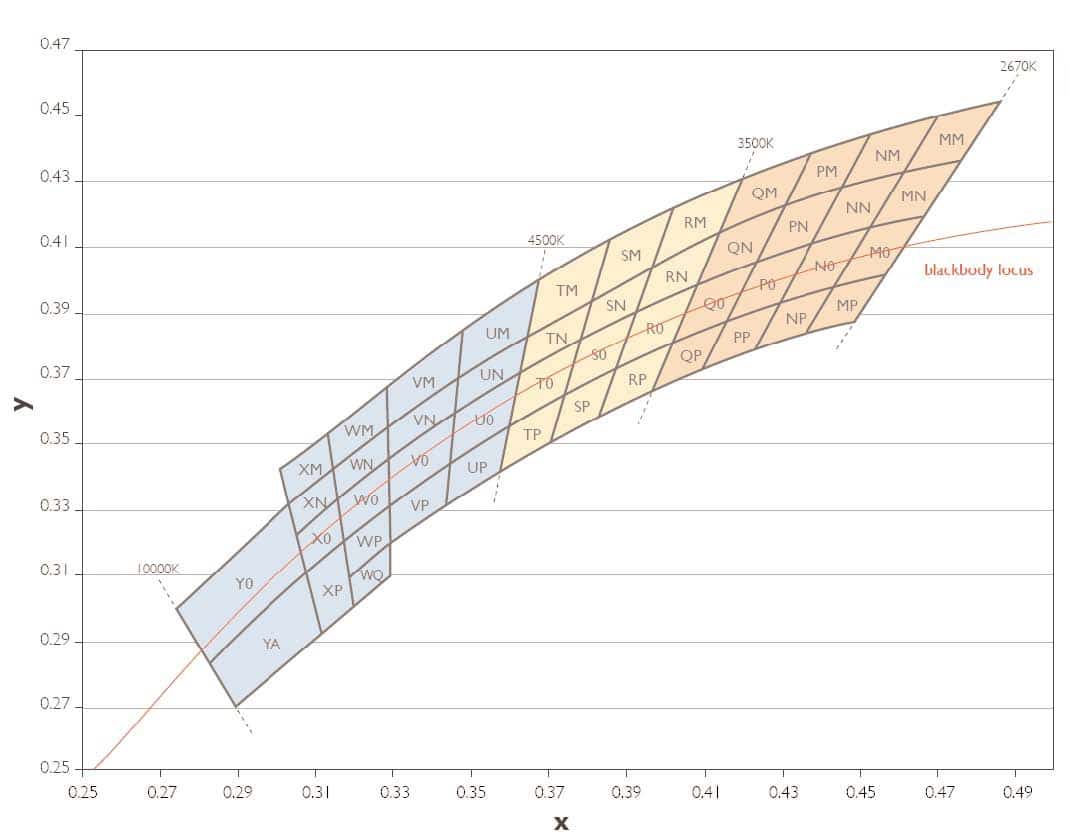

LED BINNING

White LEDs are formed when a blue LED chip is covered with a layer of phosphor during the packaging process. The tiniest variation in the phosphor layer and packaging assembly will lead to different color temperature and brightness.

Currently, creating a batch of LEDs at a uniform color temperature and brightness is a big challenge because it is not possible to perfectly control LED properties during mass production. Thus, the binning of LEDs is a practice used by LED manufacturers to manage the variation of LED performance and color at the end of the mass production process.

Each LED will be automatically sorted in a different bin based on its brightness and color temperature (See left image). It is then up to the lighting manufacturer to select the bins according to its needs. GREEN CREATIVE uses a tight binning selection for each LED type to ensure consistent color and brightness of each batch.

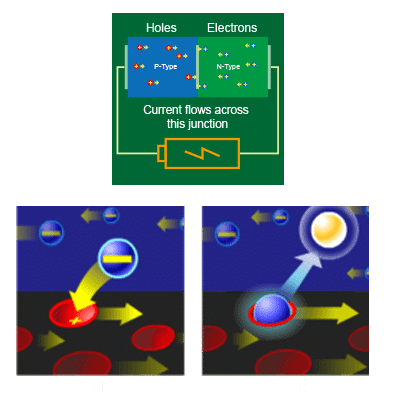

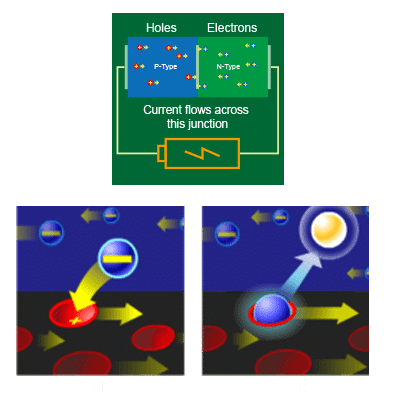

LED CHIP

LED (Light Emitting Diode) is a semiconductor diode. The chip or die consists of different layers of semiconducting materials. When current is applied, a negative layer of electrons meets a positive layer with holes at a junction (Fig. A). When an electron takes the place of a hole it drops to a lower energy level (Fig. B) releasing energy in the form of a light photon (Fig. C). This process of creating light is known as Electroluminescence.

Different semiconductor materials emit different colors of light. White LEDs used in our product are created by adding a phosphor coating on a blue LED chip.

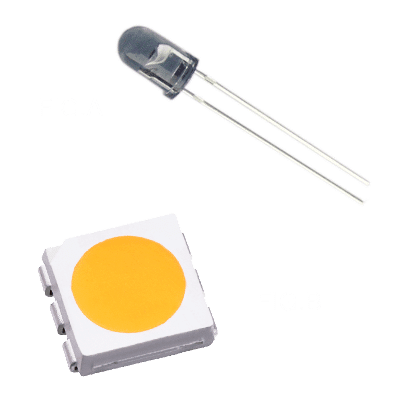

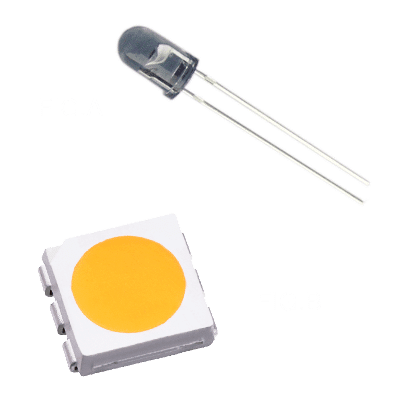

THE DIFFERENT LED TYPES

There are thousands of LED packages that come in different shapes, power and size. However, we can distinguish three main LED types: 5mm LED, SMD Low Power LED and SMD High or Medium Power LED.

THT – Through Hole Technology LED (Fig. A): The component wire leads or “legs” goes through a hole in the PCB and is soldered at the back. THT LED, also known as 5mm LED, is the earliest type of LED that was integrated in electronic devices. It is the cheapest LED available, but offers very limited lighting output and lumen output depreciates rapidly.

SMD – Surface Mount Device LED (Fig. B): The component is soldered on the surface of the PCB allowing for better heat dissipation and higher component density. Both sides of the PCB can also be used, reducing the PCB’s overall size. Assembly of SMD LED is automated using an SMT (Surface Mount Technology) assembly line for better productivity and quality control.

GREEN CREATIVE exclusively uses SMD Medium and High Power LEDs which offers both high performance and longevity needed for demanding lighting applications.

LED: A BRIGHT FUTURE

Thanks to the invention of the white LED and the enhanced lighting output improvements it provides, LED lighting has become a relevant alternative to traditional light sources, such as incandescent, fluorescent, HID and halogen.

The “Haitz law” based on observations of Roland Haitz, is the LED equivalent of the “Moore’s law” for transistors in IC. It shows that for every 10 years, LED package lighting output will increase by a factor of 20, while the cost per lumen will drop by a factor of 10.

In order to take advantage of such improvements in lighting performance and costing, LED lighting manufacturers must master a specific set of competencies and processes (see LED competencies section).