It is the total quantity of light emitted in all directions. It is measured by placing the light source at the center of an integrating sphere and is relevant for non-directional sources such as A Type Lamp or when comparing two directional sources with different beam angles.

MAKE THE RIGHT LIGHTING DECISIONS

LIGHT FLUX

LUMEN (lm)

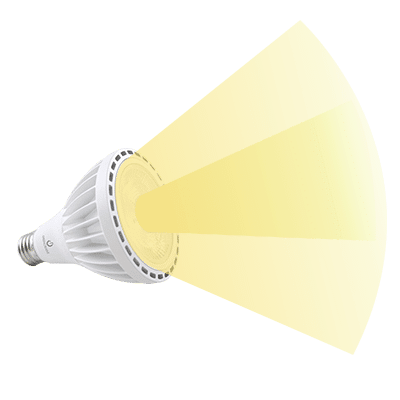

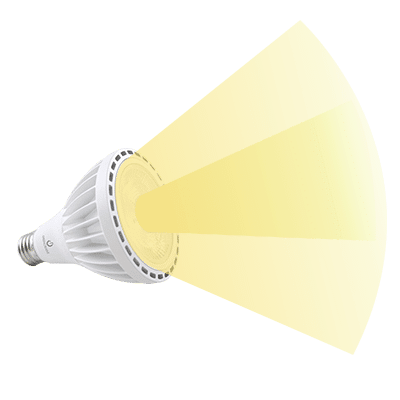

LIGHT INTENSITY

Center Beam Candela Power (CBCP) or Candela (cd)

The brightest point in the beam, usually at the center. To measure light intensity, the light source is placed inside a goniophotometer and rotated 180° to measure the light distribution and determine the brightest point. It is relevant for directional lighting such as PAR or MR16 types, but must be used in correlation with the beam angle. It is also sometimes called MBCP (Maximum Beam Candela Power).

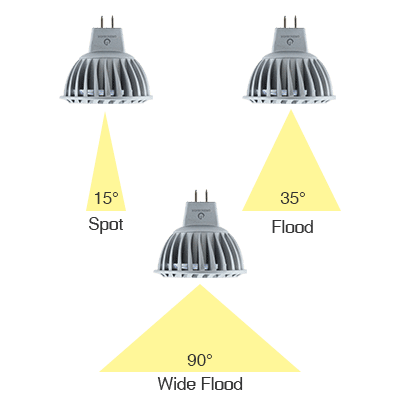

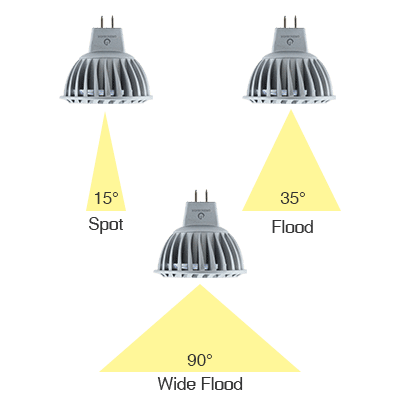

BEAM ANGLE

Degree (°)

The angle of the light emitted by the source. It is the angle passed that the goniophotometer measured intensity below 50% of the maximum (Full Width at Half Maximum). Different applications will require different beam angles, usually classified as, Spot (SP), Narrow Flood (NF), Flood (FL), and Wide Flood (WF). It is relevant for directional lighting, such as PAR and MR types. The wider the beam angle the lower the light intensity, but you will light a larger surface area.

COLOR TEMPERATURE

Degree Kelvin (K)

The color appearance of the light. This is measured in the integrating sphere, which analyzes the emitting wavelength to determine the color temperature. Incandescent and Halogen sources have a Warm White color temperature of 2700K while fluorescent and LED are available in all colors of light such as Warm White (2700K-3000K), Natural White (4000K) and Day Light (6500K).

For hospitality and Food & Beverage lighting applications, we recommend Warm White to reproduce the home comfort feeling. For retail lighting application, both Warm White and Natural White are suitable. Day Light color temperature is only used in office lighting and working environment applications, where focus and productivity is most important.

GREEN CREATIVE retrofit solutions are available in Warm White (3000K) and Natural White (4000K) as defined by ENERGY STAR® a to replace incandescent and halogen sources. Some SKU’s are also available in Warm White 2700K.

Furthermore, LED lighting output improves as color temperature is increased. The same LED will have a greater light output at 6500K than 3000K, which is why it is important to consider color temperature when comparing two LED sources.

ILLUMINANCE

Footcandles (fc) or Lux (lx)

The measure of the luminous flux density falling on a surface. Footcandles or Lux levels are tested in the goniophotometer or with a lux meter. The results can be displayed on a graph showing the illuminance level at each distance of the light source as well as the lighted area. It is used to determine the type and number of sources necessary to reach a certain illuminance target in an application. The lux levels for every project are determined by many factors, most importantly the intended use of the environment. For instance, an office illuminance requirements will be higher than a hotel room.

COLOR REPRODUCTION

Color Rendering Index (CRI or Ra)

CRI measures the ability of a light source to accurately reproduce colors and is measured on a scale from 0 to 100. Natural light has a CRI of 100 and is what all light sources strive to replicate (top picture). A CRI of 65 is considered poor (bottom picture) while a CRI of 80 is considered good. Halogen and Incandescent sources have CRIs close to 100, while fluorescent sources are usually around 80. ENERGY STAR® requires a CRI of 80 for integral LED lamps.

CRI for LED lamps is measured in an integrated sphere which analyzes the chromatic effect of the light source over a scale of 14 standard colors (R1-R14). After testing, each color receives a value. The actual CRI number is derived from taking an average of the values assigned to R1-R8.

Although the R9-R14 values are measured, they have no impact on a product’s CRI rating. R9 includes reds associated with things like food, clothing, and even skin tones. For commercial lighting, it is important to consider an LED’s CRI as well as the R9 value, especially in places like supermarkets, clothing stores, and other places where reds are prominent colors.

LIFETIME

L70 standard (hrs)

Traditional source lifetime is calculated according to the B50 standard. In this standard, the lifetime of the source is the number of operating hours after which 50% of the tested population fail.

Since LED is a semiconductor, it will not burn out like a Halogen or a CFL. Instead, lighting output will decline over time. As a result, the L70 B50 standard was developed. Based on lumen depreciation of the LED, the L70 B50 standard considers the lifetime of a source to be the number of operating hours at which half of the tested population reaches 70% of the initial lumen output (30% lumen depreciation). Below this point, it is considered that the source does not fulfill its lighting requirements and should be replaced.

Due to the extended lifetime of LED and its fast developmental pace, real application data is not always available. This is why the industry relies on the extrapolation from the LED package lumen decline data. The the higher the temperature of the LED, the faster the lumen decline, it is critical that the LEDs heat sink system is effective at dissipating heat.

EFFICACY

Lumen per Watt (LPW or lm /W)

Measure the efficiency of a source by dividing the lumen output by the total wattage consumption of the system, including the driver. A higher efficacy means you are receiving more light while using less energy to achieve it. Incandescent or halogen source efficiency is around 10-15lm / W. ENERGY STAR® requirements for integral LED lamps define minimum efficiency levels of 40-45lm / W for directional source and 50-55 lm/W for non-directional sources. GREEN CREATIVE products exceed ENERGY STAR® efficacy requirements.